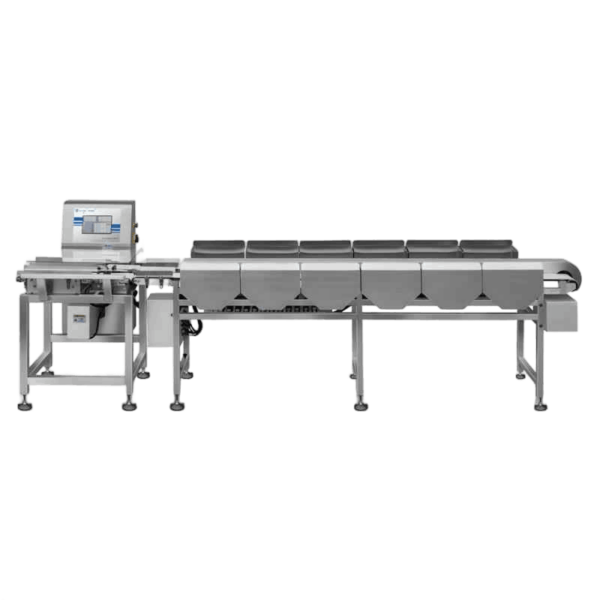

The Weight Sorting brand provides equipment that addresses the growing need for precision in production environments. Their sorter machine is crafted to handle a wide array of products, ensuring consistent weight-based grading. By automating the sorting process, it helps reduce human error and improve overall workflow, making it suitable for industries such as food processing, agriculture, and light manufacturing.

Flexible Operation for Various Products

One key aspect of the sorter machine is its adaptability. It can manage items ranging from delicate fruits to packaged goods without compromising accuracy. WEIGHT SORTING designs these machines with adjustable settings to accommodate different product sizes and weights. This flexibility allows businesses to maintain consistent quality standards while efficiently processing large volumes of items in real time.

Integration and Monitoring Capabilities

Another important feature of their sorter machine is seamless integration with existing production lines. The system supports real-time performance monitoring, enabling operators to track throughput and detect irregularities immediately. WEIGHT SORTING emphasizes machine stability and operational reliability, ensuring that production targets are met without frequent interruptions or maintenance delays.

Optimizing Output and Reducing Waste

Using a sorter machine from WEIGHT SORTING can significantly improve operational productivity. By accurately separating products according to weight, companies can minimize waste and ensure proper packaging standards. The automated process not only enhances efficiency but also provides consistent results, which is essential for maintaining product quality and customer satisfaction.

Streamlined Production with Weight Sorting Solutions

Businesses adopting WEIGHT SORTING equipment gain access to machinery that balances precision and speed. Their sorter machine offers a practical solution for improving workflow while supporting quality control. By integrating such technology, production lines become more organized, waste is reduced, and staff can focus on other critical operational tasks.