For electronics manufacturers, particularly small to medium-sized enterprises (SMEs), managing Surface Mount Device (SMD) reels effectively is not merely an organizational task; it’s a critical risk mitigation strategy. Errors in component handling directly translate to production stoppages, costly rework, and missed deadlines. Implementing a structured reel rack system is foundational to controlling this risk.

Operational Continuity via Real-Time Visibility

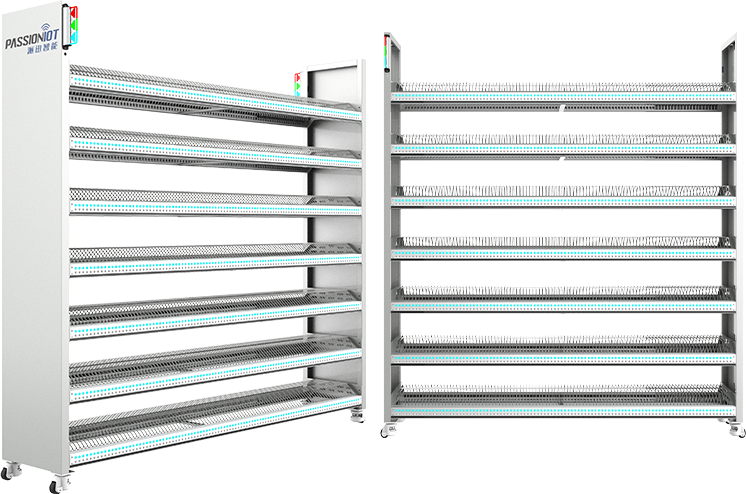

A primary source of production risk stems from inaccurate inventory – not knowing what components are available or where they are located. The PassionIOT SMD Smart Reel Rack directly addresses this vulnerability. Although manually operated, this specialized SMD reel storage rack integrates sensor technology. These sensors automatically register the placement or removal of every reel within the reel rack, providing immediate, real-time inventory status. This continuous visibility eliminates the perilous gap between manual stock checks, significantly reducing the risk of production halts due to unexpected material shortages. Knowing component availability accurately is the first line of defense against disruption.

Enforcing Process Discipline to Minimize Human Error

Beyond visibility, the PassionIOT solution introduces rigorous process control. Its core design principle enforces a strict one-to-one mapping of specific component reels to designated locations within the SMD reel storage rack. This structured approach within the reel rack environment minimizes the significant risk associated with human error during material retrieval. Technicians follow a defined path to the exact location, drastically lowering the probability of picking the wrong component – a mistake that can lead to extensive rework, scrap, and quality issues. The reel rack becomes an enforcer of correct procedure.

Conclusion

Deploying the sensor-integrated PassionIOT SMD Smart Reel Rack weaves a subtle yet resilient thread of control through the material handling process. It transforms a potential locus of vulnerability into a bastion of operational certainty, ensuring components are not just stored, but governed, allowing production to proceed with significantly reduced exposure to preventable errors and interruptions.