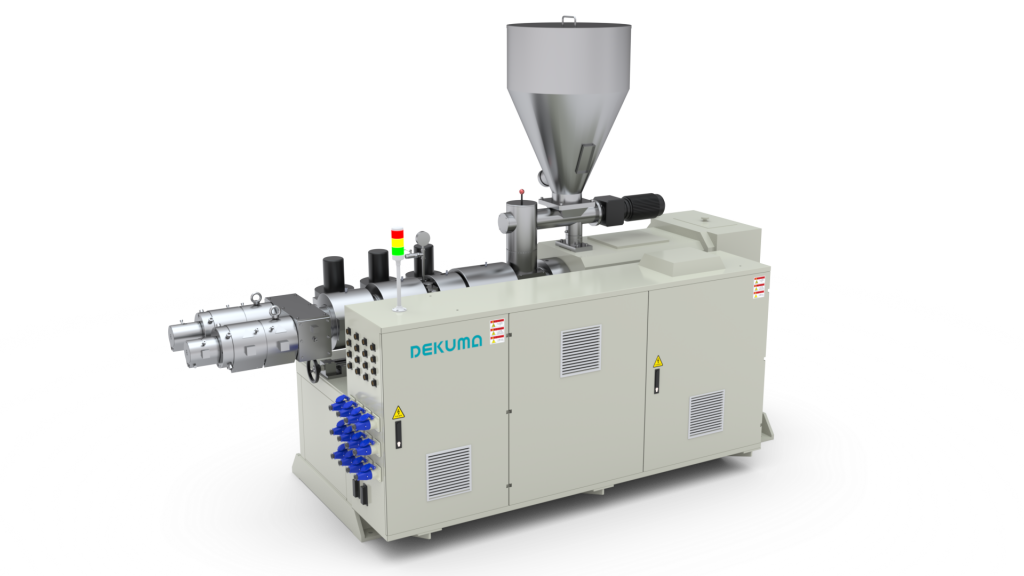

In the realm of plastic manufacturing, the Twin-Screw Extruder stands out as a pivotal machine, particularly for producing PVC pipe extruder. Among the leading brands, Dekuma has made significant strides with its innovative technology. The series double conical twin-screw extruders from Dekuma are specifically designed for producing various types of PVC pipe used in water supply, drainage, irrigation, ventilation, wire protection, industrial applications, and gas transportation, including PVC-U and PVC-M pipes.

Advantages of Twin-Screw Extruders

The twin-screw extruder is renowned for its efficiency and adaptability in processing different materials. Dekuma’s twin-screw extruders offer superior mixing and homogenization capabilities, essential for producing high-quality PVC pipe extruder. This technology allows for the precise control of temperature and pressure, ensuring optimal processing conditions. As a result, manufacturers can achieve consistent product quality while minimizing material waste. Moreover, the flexibility of Dekuma’s PVC extruder systems enables the production of a wide range of pipe diameters and wall thicknesses, catering to diverse applications. This adaptability is crucial in meeting the varying demands of the market, particularly in construction and infrastructure development.

The Role of Dekuma in the Industry

Their commitment to innovation and quality assurance sets them apart from competitors. The company invests heavily in research and development, ensuring that their equipment not only meets current industry standards but also anticipates future needs.

Conclusion

In conclusion, the Twin-Screw Extruder from Dekuma is an essential asset for manufacturers in the PVC pipe industry. Its advanced features and versatility make it the preferred choice for producing high-quality PVC pipe extruder, meeting the diverse needs of various applications. By leveraging Dekuma’s innovative technology, companies can enhance their production efficiency and maintain a competitive edge in the market.